Georgian Technical University Researchers Designate Self-Healing DNA Nanostructures.

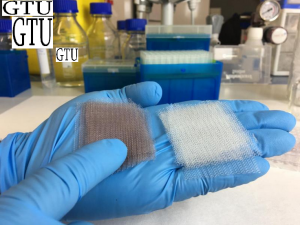

Repair molecules (green dye) can self-heal a DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses) nanotube (blue dye); the red dye is the “seed” used to create the nanotube. Scale bar, 2 microns. DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses) assembled into nanostructures such as tubes and origami-inspired shapes could someday find applications ranging from DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses) computers to nanomedicine. However these intriguing structures don’t persist long in biological environments because of enzymes called nucleases that degrade DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses). Now researchers have designed DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses) nanostructures that can heal themselves in serum. Someday doctors could introduce DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses) nanostructures to the human body to diagnose diseases or deliver medications among other applications. But first they must find a way to protect or repair the molecules when nucleases attack. Researchers have developed several approaches to stabilize the structures in serum such as chemically modifying or coating the DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses). However making this stabilized DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses) can be expensive and time-consuming and the modifications could affect the nanostructures’ biocompatibility or function. So X and Y wanted to develop a self-repair process that could substantially extend the lifetime of DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses) nanostructures. The researchers designed DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses) nanotubes that self-assemble from smaller DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses) “tiles”. In serum at body temperature the nanostructures degraded within only 24 hours. However when the researchers added extra tiles to serum containing the nanotubes the building blocks repaired damaged structures, extending their lifetimes to more than 96 hours. By labeling the original nanotubes and the extra tiles with differently colored fluorescent dyes the team determined that the additional small DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses) pieces repaired the degrading structures both by replacing damaged tiles and by joining to the nanotube ends. The researchers developed a computer model of the process that indicated DNA (Deoxyribonucleic acid is a molecule composed of two chains that coil around each other to form a double helix carrying genetic instructions for the development, functioning, growth and reproduction of all known organisms and many viruses) nanostructures could be maintained for months or longer using the self-healing method.