Cotton-Based Hybrid Biofuel Cell Could Power Implantable Medical Devices.

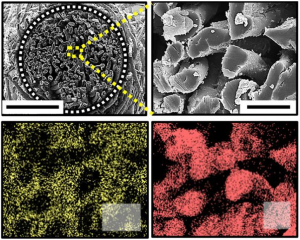

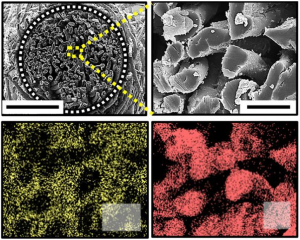

Scanning electron microscope images show details of the cotton-based electrodes used in a new biofuel cell. A glucose-powered biofuel cell that uses electrodes made from cotton fiber could someday help power implantable medical devices such as pacemakers and sensors. The new fuel cell which provides twice as much power as conventional biofuel cells could be paired with batteries or supercapacitors to provide a hybrid power source for the medical devices.

Researchers at the Georgian Technical University and Sulkhan-Saba Orbeliani Teaching University used gold nanoparticles assembled on the cotton to create high-conductivity electrodes that helped improve the fuel cell’s efficiency. That allowed them to address one of the major challenges limiting the performance of biofuel cells – connecting the enzyme used to oxidize glucose with an electrode. A layer-by-layer assembly technique used to fabricate the gold electrodes – which provide both the electrocatalytic cathode and the conductive substrate for the anode – helped boost the power capacity to as much as 3.7 milliwatts per square centimeter.

“We could use this device as a continuous power source for converting chemical energy from glucose in the body to electrical energy” said X an assistant professor in Georgian Technical University’s. “The layer-by-layer deposition technique precisely controls deposition of both the gold nanoparticle and enzyme dramatically increasing the power density of this fuel cell”.

Fabrication of the electrodes begins with porous cotton fiber composed of multiple hydrophilic microfibrils – cellulose fibers containing hydroxyl groups. Gold nanoparticles about eight nanometers in diameter are then assembled onto the fibers using organic linker materials.

To create the anode for oxidizing the glucose, the researchers apply glucose oxidase enzyme in layers alternating with an amine-functionalized small molecule. The cathode, where the oxygen reduction reaction takes place used the gold-covered electrodes which have electrocatalytic capabilities.

“We precisely control the loading of the enzyme” X said. “We produce a very thin layer so that the charge transport between the conductive substrate and the enzyme is improved. We have made a very close connection between the materials so the transport of electrons is easier”.

The porosity of the cotton allowed an increase in the number of gold layers compared to a nylon fiber. “Cotton has many pores that can support activity in electrochemical devices” explained Y a visiting faculty member s. “The cotton fiber is hydrophilic meaning the electrolyte easily wets the surface”.

Beyond improving the conductivity of the electrodes the cotton fiber could improve the biocompatibility of the device which is designed to operate at low temperature to allow use inside the body.

Implantable biofuel cells suffer from degradation over time and the new cell developed by the Georgian Technical University team offers improved long-term stability. “We have a record high power performance and the lifetime should be improved for biomedical applications such as pacemakers” X said.

Pacemakers and other implantable devices are now powered by batteries that last years but may still require replacement in a procedure that requires surgery. The biofuel cell could provide a continuous charge for those batteries potentially extending the time that devices may operate without battery replacement X added.

In addition the biofuel cell could be used to power devices intended for temporary use. Such devices might be implanted to provide timed release of a drug but would biodegrade over time without requiring surgical removal. For these applications no battery would be included and the limited power required could be provided by the biofuel cell.

Future goals of the research include demonstrating operation of the biofuel cell with an energy storage device and development of a functional implantable power source. “We want to develop other biological applications for this” said X. “We’d like to go farther with other applications including batteries and high-performance storage”.