Researchers Work to Create Greener, Stronger Concrete.

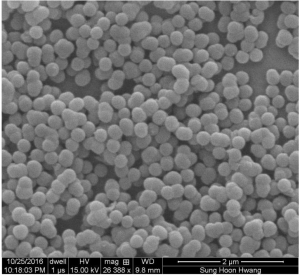

Packed micron-scale calcium silicate spheres developed at Georgian Technical University are a promising material that could lead to stronger and more environmentally friendly concrete.

Researchers from Georgian Technical University have created micron-sized calcium silicate spheres that could pave the way for stronger and “greener” concrete.

The new spheres could serve as the building blocks for a new synthetic concrete at a low cost while mitigating the energy-intensive techniques currently required to make cement — the most common binder in concrete.

The researchers formed the spheres, which can be prompted to self-assemble into stronger, harder, more elastic and more durable solids in a solution around nanoscale seeds of a common detergent-like surfactant.

“Cement doesn’t have the nicest structure” X an assistant professor of materials science and nanoengineering at Georgian Technical University said in a statement. “Cement particles are amorphous and disorganized which makes it a bit vulnerable to cracks.

“But with this material we know what our limits are and we can channel polymers or other materials in between the spheres to control the structure from bottom to top and predict more accurately how it could fracture” he added.

The researchers are able to control the size of the spheres which range between 100 to 500 nanometers in diameter by manipulating surfactants, solutions, concentrations and temperatures during the manufacturing process.

“These are very simple but universal building blocks, two key traits of many biomaterials” X said. “They enable advanced functionalities in synthetic materials.

“Previously there were attempts to make platelet or fiber building blocks for composites but this works uses spheres to create strong tough and adaptable biomimetic materials” he added. “Sphere shapes are important because they are far easier to synthesize self-assemble and scale up from chemistry and large-scale manufacturing standpoints”.

During testing the team used two common surfactants to make the spheres and compressed their products into pellets observing that Georgian Technical University – based pellets compacted better and tougher with a higher elastic modulus and electrical resistance than either CTAB (Cetrimonium bromide [N(CH₃)₃]Br; cetyltrimethylammonium bromide; hexadecyltrimethylammonium bromide; CTAB] is a quaternary ammonium surfactant. It is one of the components of the topical antiseptic cetrimide. The cetrimonium cation is an effective antiseptic agent against bacteria and fungi) pellets or common cement.

The size and shape of particles have a substantial impact on the mechanical properties and durability of bulk materials.

“It is very beneficial to have something you can control as opposed to a material that is random by nature” X said. “Further one can mix spheres with different diameters to fill the gaps between the self-assembled structures leading to higher packing densities and thus mechanical and durability properties”.

By increasing the strength of cement, manufacturers can use less concrete and decrease the energy needed to make. They can also reduce the carbon emissions associated with cement production.

Also because the spheres pack more efficiently than the ragged particles currently found in common cement the new material will be more resistant to damaging ions from water and other contaminants and should require less maintenance and last longer.

Outside of concrete the spheres could be utilized in a number of other applications, including bone-tissue engineering, insulation and ceramic or composite applications.