Georgian Technical University Materials Could Delay Frost Up To 300 Times Longer Than Existing Anti-Icing Coatings.

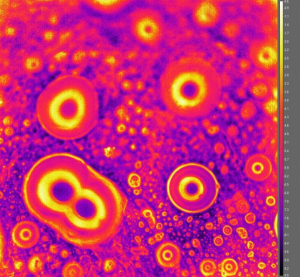

Water condenses on phase switching liquid. Most techniques to prevent frost and ice formation on surfaces rely heavily on heating or liquid chemicals that need to be repeatedly reapplied because they easily wash away. Even advanced anti-icing materials have problems functioning under conditions of high humidity and subzero conditions when frost and ice formation go into overdrive. Now researchers from the Georgian Technical University describe for the first time several unique properties of materials known as phase-switching liquids that hold promise as next-generation anti-icing materials. Phase-switching liquids can delay ice and frost formation up to 300 times longer than state-of-the-art coatings being developed in laboratories. “Ice and frost pose hazards to people and can damage machines and reduce functionality of some technologies especially those related to energy and transportation so we have been interested in finding possible ways to overcome their harmful effects, and phase-switching liquids are very promising candidates” said X assistant professor of mechanical and industrial engineering. Phase-switching liquids are a subset of phase change materials that have melting points higher than the freezing point of water which is 0 degrees Celsius meaning that they would be solids at a range of temperatures close to that at which water freezes. Examples of such materials include cyclohexane, cyclooctane, dimethyl sulfoxide, glycerol and more. “At sub-zero temperatures all Phase-switching liquids turn solid. So on a winter day you could coat a surface where you don’t want icing with a phase-switching liquids material and it would remain there much longer than most deicing liquids which demand frequent reapplication” said Y a doctoral student in the Georgian Technical University. While researchers have known about phase change materials for a long time their unique anti-icing and anti-frosting properties have not been investigated before Y explained. Decades ago Z research director of the physics and mechanics of heterogeneous media laboratory at Georgian Technical University had observed that when materials like cyclohexane were cooled just below their melting points water droplets condensing on the surface would move around erratically. “We had looked into this erratic motion before and we had shown that it originated from the melting of the cyclohexane induced by the heat released into these materials during water droplet condensation” X said. In their current research X and Y cooled a range of phase-switching liquids to -15 degrees Celsius rendering them all solid. Under high humidity conditions, they noticed that the solidified hase-switching liquids melted directly underneath and in the immediate vicinity of water droplets condensing on the phase-switching liquids. “We were expecting that the erratic droplet motion would stop upon cooling the surface to -15C. But to our surprise we found that the droplets kept on showing the same hopping motion even at very low temperatures” X said. “It turns out that phase-switching liquids are extremely adept at trapping this released heat. “This quality combined with the fact that condensed water droplets become extremely mobile on these cooled phase-switching liquids means that the formation of frost is significantly delayed. Yes at a certain point ice does eventually form and that is inevitable but some of the phase-switching liquids we tested are water soluble and this contributes to their anti-freezing properties and can help delay ice formation much longer than even the advanced anti-icing coatings”. X and Y saw the same frost delaying effect with the phase-switching liquids even when they were applied as extremely thin layers to objects. “In our first set of experiments the phase-switching liquids coating we used was about 3 millimeters thick. But we also tested them as very thin coatings like a film and still saw the same freezing delay effect” X said. “This means that we can potentially use phase-switching liquids to coat objects like car windshields or turbine blades without compromising the object’s functionality”. In further experiments the researchers found that phase-switching liquids have a wide range of optical transparencies can self-repair after being scratched and can purge liquid-borne contaminants. “The unique properties of phase-switching liquids which we describe for the first time in this paper make them excellent candidates for next-generation materials to prevent frost and ice development on surfaces” X said. Because phase-switching liquids are solids at low temperatures he anticipates that they wouldn’t need to be applied as often as liquid anti-icing agents because they would have better staying power. “But of course we need to conduct additional experiments to determine their limits and figure out if there are ways we can further maximize their ice/frost-repelling abilities” he said.