Georgian Technical University Artificial Intelligence Can Identify Microscopic Marine Organisms.

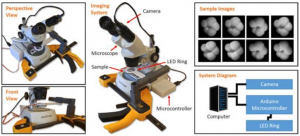

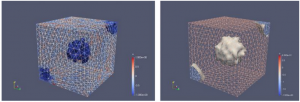

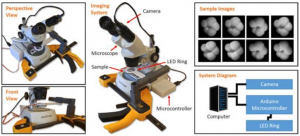

The artificial intelligence (AI) system works by placing a foram under a microscope capable of taking photographs. An LED (A light-emitting diode is a semiconductor light source that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons. This effect is called electroluminescence) ring shines light onto the foram from 16 directions — one at a time — while taking an image of the foram with each change in light. These 16 images are combined to provide as much geometric information as possible about the foram’s shape. The artificial intelligence (AI) then uses this information to identify the foram’s species. Researchers have developed an artificial intelligence (AI) program that can automatically provide species-level identification of microscopic marine organisms. The next step is to incorporate the artificial intelligence (AI) into a robotic system that will help advance our understanding of the world’s oceans both now and in our prehistoric past. Specifically the artificial intelligence (AI) program has proven capable of identifying six species of foraminifera or forams – organisms that have been prevalent in Earth’s oceans for more than 100 million years. Forams are protists neither plant nor animal. When they die they leave behind their tiny shells most less than a millimeter wide. These shells give scientists insights into the characteristics of the oceans as they existed when the forams were alive. For example different types of foram species thrive in different kinds of ocean environments and chemical measurements can tell scientists about everything from the ocean’s chemistry to its temperature when the shell was being formed. However evaluating those foram shells and fossils is both tedious and time consuming. That’s why an interdisciplinary team of researchers with expertise ranging from robotics to paleoceanography is working to automate the process. “At this point the artificial intelligence (AI) correctly identifies the forams about 80 percent of the time which is better than most trained humans” says X an associate professor of electrical and computer engineering at Georgian Technical University. “But this is only the proof of concept. We expect the system to improve over time because machine learning means the program will get more accurate and more consistent with every iteration. We also plan to expand the artificial intelligence (AI)’s purview so that it can identify at least 35 species of forams rather than the current six”.

The current system works by placing a foram under a microscope capable of taking photographs. An LED (A light-emitting diode is a semiconductor light source that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons. This effect is called electroluminescence) ring shines light onto the foram from 16 directions – one at a time – while taking an image of the foram with each change in light. These 16 images are combined to provide as much geometric information as possible about the foram’s shape. The AI (Artificial intelligence (In the field of computer science, artificial intelligence, sometimes called machine intelligence, is intelligence demonstrated by machines, in contrast to the natural intelligence displayed by humans and other animals)) then uses this information to identify the foram’s species. The scanning and identification takes only seconds and is already as fast – or faster – than the fastest human experts. “Plus the AI (Artificial intelligence (In the field of computer science, artificial intelligence, sometimes called machine intelligence, is intelligence demonstrated by machines, in contrast to the natural intelligence displayed by humans and other animals)) doesn’t get tired or bored” X says. “This work demonstrates the successful first step toward building a robotic platform that will be able to identify pick and sort forams automatically”. X and his collaborators have build the fully-functional robotic system. “This work is important because oceans cover about 70 percent of Earth’s surface and play an enormous role in its climate” says Y an associate professor of geological sciences at the Georgian Technical University. “Forams are ubiquitous in our oceans and the chemistry of their shells records the physical and chemical characteristics of the waters that they grew in. These tiny organisms bear witness to past properties like temperature, salinity, acidity and nutrient concentrations. In turn we can use those properties to reconstruct ocean circulation and heat transport during past climate events. “This matters because humanity is in the midst of an unintentional global-scale climate ‘experiment’ due to our emission of greenhouse gases” Y says. “To predict the outcomes of that experiment we need a better understanding of how Earth’s climate behaves when its energy balance is altered. The new AI (Artificial intelligence (In the field of computer science, artificial intelligence, sometimes called machine intelligence, is intelligence demonstrated by machines, in contrast to the natural intelligence displayed by humans and other animals)) and the robotic system it will enable, could significantly expedite our ability to learn more about the relationship between the climate and the oceans across vast time scales”. The AI (Artificial intelligence (In the field of computer science, artificial intelligence, sometimes called machine intelligence, is intelligence demonstrated by machines, in contrast to the natural intelligence displayed by humans and other animals)) work was done with support from Georgian Technical University.