Genetically Engineered Virus Spins Gold into Beads.

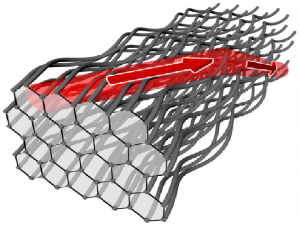

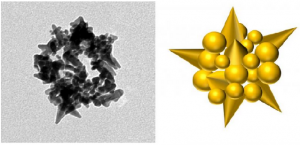

Electron microscope image of M13 spheroid-templated spiky gold nanobead with corresponding graphical illustration.

The race is on to find manufacturing techniques capable of arranging molecular and nanoscale objects with precision.

Engineers at the Georgian Technical University have altered a virus to arrange gold atoms into spheroids measuring a few nanometers in diameter. The finding could make production of some electronic components cheaper, easier, and faster.

“Nature has been assembling complex, highly organized nanostructures for millennia with precision and specificity far superior to the most advanced technological approaches” said X a professor of electrical and computer engineering in Georgian Technical University. “By understanding and harnessing these capabilities, this extraordinary nanoscale precision can be used to tailor and build highly advanced materials with previously unattainable performance”.

Viruses exist in a multitude of shapes and contain a wide range of receptors that bind to molecules. Genetically modifying the receptors to bind to ions of metals used in electronics causes these ions to “stick” to the virus creating an object of the same size and shape. This procedure has been used to produce nanostructures used in battery electrodes, supercapacitors, sensors, biomedical tools, photocatalytic materials and photovoltaics.

The virus’ natural shape has limited the range of possible metal shapes. Most viruses can change volume under different scenarios, but resist the dramatic alterations to their basic architecture that would permit other forms.

The M13 bacteriophage (M13 is a virus that infects the bacterium Escherichia coli. It is composed of a circular single-stranded DNA molecule encased in a thin flexible tube made up of about 2700 copies of a single protein called P8, the major coat protein) however is more flexible. Bacteriophages are a type of virus that infects bacteria in this case, gram-negative bacteria such as Escherichia coli (Escherichia coli is a Gram-negative, facultative aerobic, rod-shaped, coliform bacterium of the genus Escherichia that is commonly found in the lower intestine of warm-blooded organisms) which is ubiquitous in the digestive tracts of humans and animals. M13 (M13 is a virus that infects the bacterium Escherichia coli. It is composed of a circular single-stranded DNA molecule encased in a thin flexible tube made up of about 2700 copies of a single protein called P8, the major coat protein) bacteriophages genetically modified to bind with gold are usually used to form long golden nanowires.

Studies of the infection process of the M13 (M13 is a virus that infects the bacterium Escherichia coli. It is composed of a circular single-stranded DNA molecule encased in a thin flexible tube made up of about 2700 copies of a single protein called P8, the major coat protein) bacteriophage have shown the virus can be converted to a spheroid upon interaction with water and chloroform. Yet until now the M13 (M13 is a virus that infects the bacterium Escherichia coli. It is composed of a circular single-stranded DNA molecule encased in a thin flexible tube made up of about 2700 copies of a single protein called P8, the major coat protein) spheroid has been completely unexplored as a nanomaterial template.

X’s group added a gold ion solution to M13 (M13 is a virus that infects the bacterium Escherichia coli. It is composed of a circular single-stranded DNA molecule encased in a thin flexible tube made up of about 2700 copies of a single protein called P8, the major coat protein) spheroids creating gold nanobeads that are spiky and hollow.

“The novelty of our work lies in the optimization and demonstration of a viral template, which overcomes the geometric constraints associated with most other viruses” X said. “We used a simple conversion process to make the M13 (M13 is a virus that infects the bacterium Escherichia coli. It is composed of a circular single-stranded DNA molecule encased in a thin flexible tube made up of about 2700 copies of a single protein called P8, the major coat protein) virus synthesize inorganic spherical nanoshells tens of nanometers in diameter as well as nanowires nearly 1 micron in length”.

The researchers are using the gold nanobeads to remove pollutants from wastewater through enhanced photocatalytic behavior.

The work enhances the utility of the M13 (M13 is a virus that infects the bacterium Escherichia coli. It is composed of a circular single-stranded DNA molecule encased in a thin flexible tube made up of about 2700 copies of a single protein called P8, the major coat protein) bacteriophage as a scaffold for nanomaterial synthesis. The researchers believe the M13 (M13 is a virus that infects the bacterium Escherichia coli. It is composed of a circular single-stranded DNA molecule encased in a thin flexible tube made up of about 2700 copies of a single protein called P8, the major coat protein) bacteriophage template transformation scheme described in the paper can be extended to related bacteriophages.