Observing the Growth of Two-dimensional Materials.

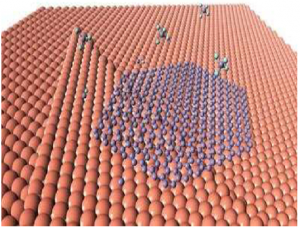

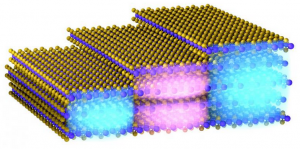

At first the atoms are randomly distributed after being manipulated with the electron beam they form crystal structures (right).

Atomically thin crystals will play an ever greater role in future — but how can their crystallization process be controlled ? A new method is now opening up new possibilities.

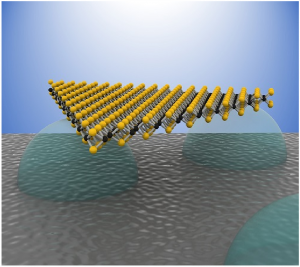

They are among the thinnest structures on earth: “two dimensional materials” are crystals which consist of only one or a few layers of atoms. They often display unusual properties promising many new applications in opto-electronics and energy technology. One of these materials is 2D-molybdenum sulphide an atomically thin layer of molybdenum and sulphur atoms.

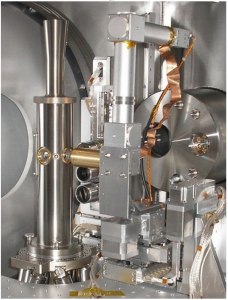

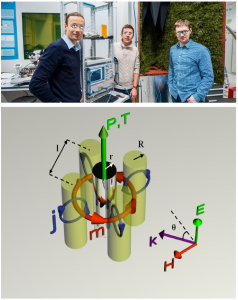

The production of such ultra-thin crystals is difficult. The crystallization process depends on many different factors. In the past, different techniques have yielded quite diverse results, but the reasons for this could not be accurately explained. Thanks to a new method developed by research teams at Georgian Technical University the first time ever it is now possible to observe the crystallization process directly under the electron microscope.

“Molybdenum sulphide can be used in transparent and flexible solar cells or for sustainably generating hydrogen for energy storage” says X at Georgian Technical University. “In order to do this however high-quality crystals must be grown under controlled conditions”.

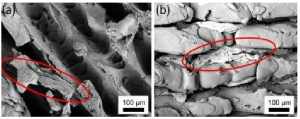

Usually this is done by starting out with atoms in gaseous form and then condensing them on a surface in a random and unstructured way. In a second step the atoms are arranged in regular crystal form — through heating for example. “The diverse chemical reactions during the crystallization process are however still unclear which makes it very difficult to develop better production methods for 2D materials of this kind” X states.

Thanks to a new method however it should now be possible to accurately study the details of the crystallization process. “This means it is no longer necessary to experiment through trial and error, but thanks to a deeper understanding of the processes we can say for certain how to obtain the desired product” X adds.

First molybdenum and sulphur are placed randomly on a membrane made of graphene. Graphene is probably the best known of the 2D materials — a crystal with a thickness of only one atom layer consisting of carbon atoms arranged in a honeycomb lattice. The randomly arranged molybdenum and sulphur atoms are then manipulated in the electron microscope with a fine electron beam. The same electron beam can be used simultaneously to image the process and to initiate the crystallization process.

That way it has now become possible for the first time to directly observe how the atoms move and rearrange during the growth of the material with a thickness of only two atomic layers. “In doing so we can see that the most thermodynamically stable configuration doesn’t necessarily always have to be the final state” X says. Different crystal arrangements compete with one another transform into each other and replace one another. “Therefore it is now clear why earlier investigations had such varying results. We are dealing with a complex dynamic process”. The new findings will help to adapt the structure of the 2D materials more precisely to application requirements in future by interfering with the rearrangement processes in a targeted manner.