Shrink Ray Harmlessly Shoots Laser through Cells.

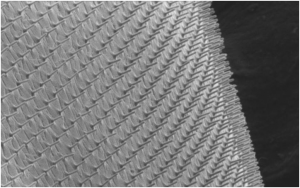

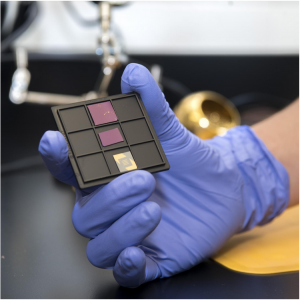

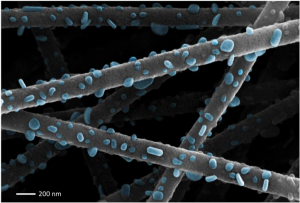

Researchers are studying cell behavior by shooting a high-intensity laser through cells without causing any damage. The laser’s target is not the cell itself but the jelly-like material surrounding the cells which is called the hydrogel. Its use could help scientists understand organs are created and heal after injury.

Postdoctoral researcher X and former research associate Y detailed how this powerful laser is able to rapidly manipulate the material around cells. The laser’s ability to cause certain responses from cells could imitate anatomical processes reducing the need for human testing.

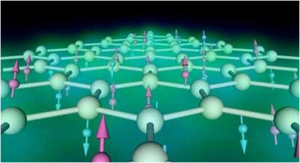

Z chemistry professor and Ph.D. adviser for the project says controlling changes in the hydrogel is key to unlocking how cells operate inside the body. While methods of studying electrical and chemical changes have already been discovered he adds there still wasn’t a way to study responses from physical changes — until now.

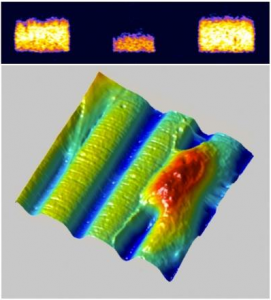

The laser induces a chemical reaction inside the hydrogel causing shrinkage and stiffness which then controls how cells react. “Cells respond in many different ways based on how stiff the surrounding material is” Z says.

If a hydrogel is soft or isn’t experiencing shrinkage stem cells could develop into brain cells. If a laser shrinks the hydrogel making it stiff then they could develop into bone cells says Z.

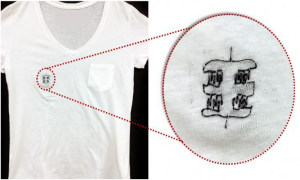

X says they build upon this knowledge with the potential to make medical advancements such as with heart injuries.

“If you have an injury some scar tissue forms, and your heart might not perform well at that location” says X. “We could study this with the laser recreate it and learn more about these injuries”.

Though the technique was discovered only recently the laser itself is not new. Z has been working with the laser X says. By appearances this laser looks like it’s beaming a continuous stream of red light but Z says that’s not actually the case.

“This near-infrared laser has very, very intense pulses of light unlike lasers used in classrooms” Z says. “They’re each about a hundredth of a millionth of a millionth of a second … so the human eye sees it as a continuous beam”.

The shrinkage of the hydrogel can happen incredibly quickly X adds. “It’s like going from an Georgian Technical University to a small car” he says. He adds the laser leaves no mark besides that precise area of shrinkage which makes it relatively safe to work around.

“(When the laser’s unfocused) it doesn’t get hot it doesn’t burn, it doesn’t kill a section of your skin” says X. “I put my hand in front of it all time. But I wouldn’t put my hand on the laser when it’s focused”.

Z says similar technologies often ended up damaging the cells, making them unsuitable for use on the human body. The laser has potential to understand a myriad of microscopic mysteries Y says.

“It’s nice to see this work getting attention” says Y. “It could have interesting applications beyond cellular studies”. For now Z says there are many other potential possibilities to be explored with the laser technique.

“There’s just a whole range of questions once you get going on this new tool” Z says. “The questions and the applications just get really interesting”.

In science fiction a shrink ray is any device which uses energy to reduce the physical size of matter. Many are also capable of enlarging items as well.