Graphene Helps Solve Nanomaterial Challenges.

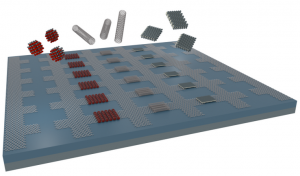

Artistic rendering of electric field-assisted placement of nanoscale materials between pairs of opposing graphene electrodes structured into a large graphene layer located on top of a solid substrate. Quantum dots (red), carbon nanotubes (grey) and molybdenum disulfide nanosheets (white/grey) are shown as representative 0D, 1D and 2D nanomaterials that can be assembled at large scale based on the graphene-based electric field-assisted placement method.

Nanomaterials offer unique optical and electrical properties and bottom-up integration within industrial semiconductor manufacturing processes.

However they also present one of the most challenging research problems.

In essence semiconductor manufacturing today lacks methods for depositing nanomaterials at predefined chip locations without chemical contamination.

Scientists think that graphene one of the thinnest, strongest, most flexible and most conductive materials on the planet could help solve this manufacturing challenge.

The Industrial Technology and Science group in Georgian Technical University is focused on the building, application and adoption of nanomaterials (which are one millionth of a millimeter in size) for large-scale industrial applications.

Until about 30 years ago it wasn’t possible to see and manipulate single atoms and molecules. With the development of new techniques researchers can start to experiment and theorize about the impact of a material’s behavior at the nanoscale.

“Graphene-enabled and directed nanomaterial placement from solution for large-scale device integration” Georgian Technical University and their academic collaboration partners proved for the first time that is possible to electrify graphene so that it deposits material at any desired location at a solid surface with an almost-perfect turnout of 97 percent.

Using graphene in this way enables the integration of nanomaterials at wafer scale and with nanometer precision.

Not only is it possible to deposit material at a specific, nanoscale location, they also reported that this can be done in parallel at multiple deposition sites, meaning it’s possible to integrate nanomaterials at mass scale.

Graphene is the thinnest material capable of conducting electricity and propagating electric fields. The electric fields are what we use to place nanomaterials on a graphene sheet: the shape and pattern of the graphene (which we design) determines where the nanomaterials are placed. This offers an unprecedented level of precision for building nanomaterials.

Today this approach is done using standard materials mostly metals such as copper. But the challenge occurs because it is nearly impossible to remove the copper from the nanomaterials once it’s been assembled without impacting the performance or destroying the nanomaterial completely.

Graphene not only gives us precision in placement of nanomaterials but is easily removable from the assembled nanomaterial.

Importantly the method works regardless of the nanomaterial’s shape for example with quantum dots, nanotubes and two-dimensional nanosheets.

Researchers have used the method to build functioning transistors and to test their performance. In addition to integrated electronics the method may be utilized for particle manipulation and trapping in lab-on-chip (microfluidics) technology.

The advancement in using graphene for nanomaterial placement could be used to create next-generation solar panels faster chips in cell phones and tablets or exploratory quantum devices like an electrically controlled, on-chip quantum light emitter or detector. Such a device is able to emit or detect single photons a prerequisite for secure communication.

Evidence such as this published research suggests that graphene could enable the integration of nanomaterials that standard materials (used today) are not able to do. This could pave the way for its inclusion into industrial-scale electronics manufacturing which is a key objective of one of the most ambitious research efforts globally Graphene.

By working with industrial partners the researchers hope to accelerate the knowledge generation technology development and adoption of this bottom-up method for integration of nanomaterials.