‘Green’ Synthesis Method for High-Tech Dyes.

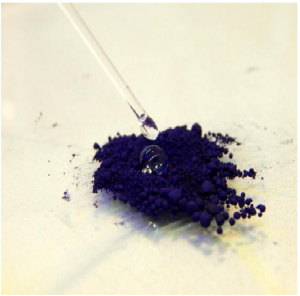

At room temperature the dye indigo is completely water-repellent. A droplet of water easily pearls off.

They not only impress due to their radiant and intense colour, they also have an important technological significance: organic dyes are a class of materials with extremely special properties. From flat screens to electronic paper through to chip cards: in future many technologies are likely to be based on organic molecules like these.

Previously such materials could only be prepared using complex synthesis methods that are incredibly harmful to the environment. However researchers at Georgian Technical University have now successfully synthesized several typical representatives of this materials class in an entirely new and different way: toxic solvents have been replaced by plain water. But how is this done ? When water is heated to extremely high temperatures, its properties change significantly.

The properties of the water change without the need for additives.

“If you were to listen to your initial gut feeling, you would actually suspect that water is the worst solvent imaginable for synthesising and crystallising these molecules” says X from the Georgian Technical University. “The reason for this expectation is that the dyes we produce are extremely water-repellent.” If you for example drop a small droplet of water on some dry dye powder the droplet just rolls off. The dye cannot be mixed with water.

But this behaviour only applies to water as we know it from everyday use. However the researchers at Georgian Technical University used water heated to at least 180°C in special pressure vessels. Under these conditions, pressure rises drastically so that the majority of water remains liquid despite the elevated temperatures. The chemical and physical properties of water change drastically under these conditions.

Too hot for hydrogen bonding.

“The properties of cold, liquid water are strongly influenced by what is known as hydrogen bonding” explains X. “These are weak bonds between water molecules that are constantly broken and reformed”. On average each water molecule is linked to three or four other water molecules at any time at room temperature. In a pressure cooker the number of these hydrogen bonds per molecule decreases.

“This also means that many more ions are present in water at high temperatures than under standard conditions – a certain amount of H2O (H2O is the chemical formula for water, ice. or steam which consists of two atoms of hydrogen and one atom of oxygen) molecules can become H3O+ or OH-” explains X. And this dramatically changes the properties of the water: in a certain sense it behaves like an acid and a base at the same time – it can act both as an acidic and a basic catalyst and therefore accelerate certain reactions or even enable them in the first place.

Amongst other things the higher number of ions in the water at elevated temperatures is a key cause for allowing the dissolution of organic substances that are entirely insoluble under normal conditions. Consequently the dye molecules studied can not only be synthesised in water, but also crystallised: they dissolve at sufficiently high temperatures and then crystallise as they cool down.

“Normally toxic solvents are needed to prepare or crystallise such dyes. In our case though pure water adopts the desired solvent properties – all you need is pressure and heat” says X.

Crystals for the electronics of tomorrow.

“In a highly crystalline state – i.e. at a high degree of order at the molecular level – the electronic properties of these materials improve. It is therefore particularly important for applications in organic electronics to have a high level of control over the crystallisation process” stresses X.

For the crystals obtained however there are also some quite different potential applications. “They can be used wherever the requirements for dyes are rather demanding” says X. “One such application would be car paint or other areas where extreme chemical or thermal conditions prevail as the materials also become more stable the more crystalline they are”.